Hi folks, Katherine Rice here. CAMECA is a participant in a program sponsored by our parent company, AMETEK. They want to hire great engineers, so they have designed a three-year program so that new engineering grads can experience different facets of AMETEK. Here I sit down for a Q&A with our third engineering management program associate, Trung Le, to talk about his experience with us. I’ll let you hear from one of the bright young stars of AMETEK about his thoughts on atom probe and joining the workforce. We have had a great experience welcoming these younger members of the community into our lab, and we always get a bit sad when they must move on to their next adventure.

KR: Tell me about the EMP program and how you became interested in it?

TL: The Engineering Management Program (EMP) is a 3-year rotational program designed by AMETEK for recent engineering graduates, throughout which they will get to work on different cutting-edge technologies, explore the different roles that an engineer can take on, and collaborate alongside with some of the most brilliant minds. As a recent Electrical Engineering graduate, I have had the opportunity to work on a variety of different, and very exciting technologies, ranging from fully self-driving formula race cars to smart heat pumps that can warm up your home water source with solar panels waste heat. I find the idea of continuously being exposed to the different ways that engineering can benefit our world very exciting, and being a part of the EMP program surely facilitates this exposure. Three years, three different types of technology! I’m also a very adventurous guy so being able to explore the different parts of the country is also a plus!

KR: Coming from someone with no atom probe or electron microscopy background, how have you liked learning about this technology?

TL: Like many of other folks who have zero background in atom probe tomography (APT), we mostly learned about atoms from our general chemistry courses back in high school. And I believe we all agree that none of us has ever really “seen” an atom before, we just sort of… accepted it when it was taught to us. This is why joining CAMECA and learning about the atom probe technology has been such an exciting and mind-blowing experience for me. Atoms are the building blocks of the universe and finally being able to visualize their mass and positions in 3D space is for sure one of the coolest things I have ever done. Learning about the application of APT to the field of semiconductor manufacturing in particular, and applications to metals has also made my experience at CAMECA a lot more meaningful, knowing my work will indirectly contribute to many other great technological advancements!

KR: What projects are you working on?

TL: I have been working on developing custom scripts that can automate the atom probe data collection process for the Applications team and the manufacturing team. When operating an atom probe, the user will typically sit in front of its control PC, monitor the data collection process of their sample, and apply the appropriate acquisition conditions as needed, such as the laser pulse energy, voltage, etc. This manual monitoring can get tedious quickly if they are collecting a large amount of data and need to vary their acquisition conditions based on some feedback, since each data collection process can take hours or even overnight! With the help of scripted acquisition, an automation feature of the atom probe that allows users to write custom automation scripts, the user can “instruct” the atom probe on what to do and when to do it. This way, the users can quickly scale up their data collection process without sacrificing valuable time. Using this handy automation feature, I have written scripts that allow our Application Scientists to automate their internal studies on boron and phosphorous, and I have helped our manufacturing engineers automate their QA process for newly assembled Atom Probes. I have also made a lot of instructional videos for our users on how to make full use of the scripted acquisition feature. Note from Katherine, see Trung's videos in the Thinkific course on Automation, available for automation and scripted acquisition users.

Trung Le coding up a storm to step through acquisition conditions on GaN

KR: What was the best and worst part?

TL: The best part about my job here will have to be operating the atom probe, collecting data, and making specimens! Making atom probe specimens always has me in awe, considering that I am handling a piece of material about 1000 times smaller than the diameter of my hair with great dexterity. Operating the atom probe is always fun since I am always reminded of how remarkable this technology is, atoms are not something you get to “see” every day! For the worst part about my job…. It will have to be waiting for my turn to use our tools. Our demos and visits come first, so it sometimes it can take a long time before I can use the instrument for internal studies.

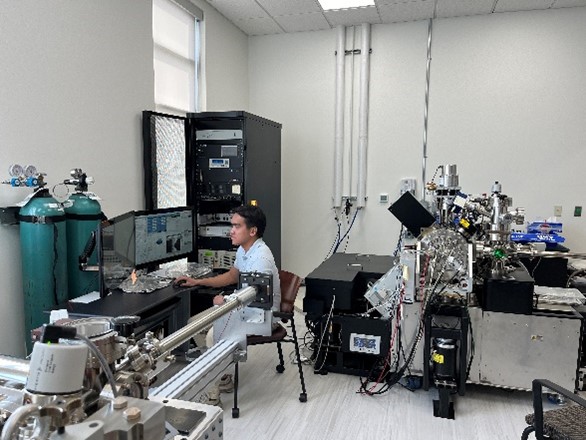

Trung Le in the lab

KR: What would you tell newcomers to the field of Atom Probe?

TL: Atom probe tomography is truly for everyone, not just for material scientists. Don’t be intimidated by the sheer size of the instrument or the complex theory behind the technology. CAMECA has developed a very intuitive user interface for their Atom Probe control software and built a large library of online learning resources that users can access from anywhere. Plus, the personal support offered by the brilliant minds from our Applications team will get newcomers up to speed in no time. If I, an electrical engineer with completely zero background in the field of atom probe or material science prior to joining CAMECA, can operate the atom probe, then anyone can!

Isabelle Martin, Trung Le, Stella Seo, Yi Wang, Katherine Rice, and Sunil Gudur work on the LEAP 6000 XR in January 2024

KR: So, you have a few months left here, what do you want to learn in the coming time before your next rotation?

TL: Well, during the past 8 months that I have been here at CAMECA, I have had the opportunity to do a lot of exciting work, from preparing nano-scale atom probe samples and collecting data to writing custom automation scripts. In addition to those skills, I think it would be very cool if I could learn more about the manufacturing process of our atom probes. Being knowledgeable about how the atom probes are built from the ground up will definitely make my journey here very well rounded, as I can tell people that I can both operate the atom probe and tell them how it is built. Thanks very much, Trung. You are a valuable member of our team and we are glad to have you.

To learn more about the EMP program check out: https://youtu.be/AMaxpQ7-sRQ

To get familiar with Atom Probe Tomography in less than 3 minutes, watch our whiteboard animation: https://www.youtube.com/watch?v=CXiDO4vjfVg

Authors: Trung LE

Other Participants/Contributors: Katherine RICE